FROM IDEA TO PRODUCT

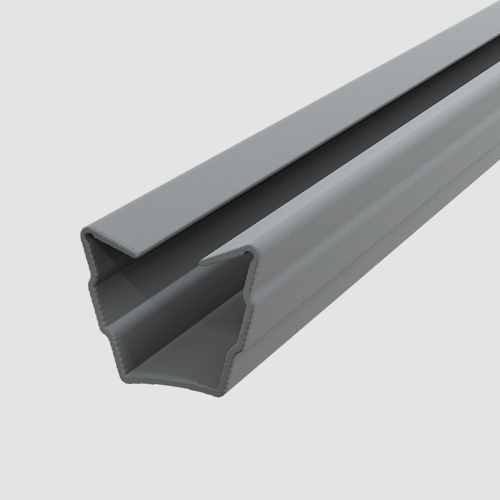

PACKAGING

SOLUTIONS

FOR AUTOMATION

OPTIMAL DEVELOPMENT &

USE FOR YOUR PRODUCTS

From Idea to Solution

From Idea to Solution

In our design department, we develop one-stop series products and fully-comprehensive custom solutions for our clients, from engineering to logistics.

Whether you have a concrete solution in mind or just a basic idea, our experienced plastics specialists provide quick, flexible, efficient and reliable advice on implementation options, material properties, manufacturing, or customisation.

Take advantage of our technological know-how and custom

production methods in Kitzingen, centrally located in Germany.

Michael Back & Stefan Mey

Management

Rothe as

System supplier

System supplier

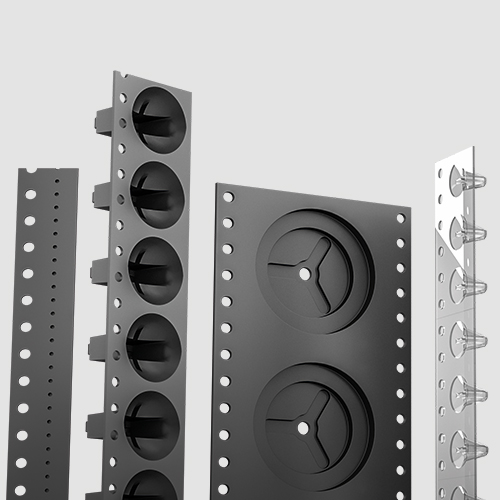

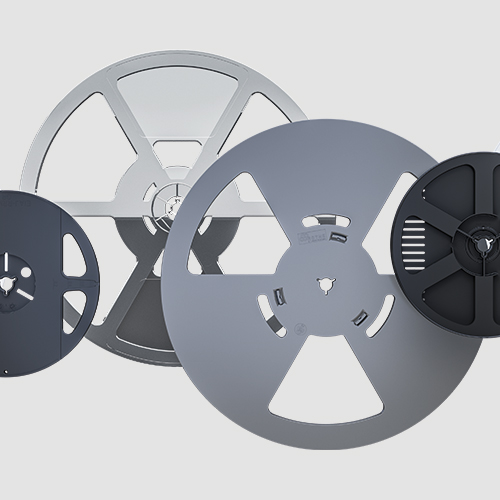

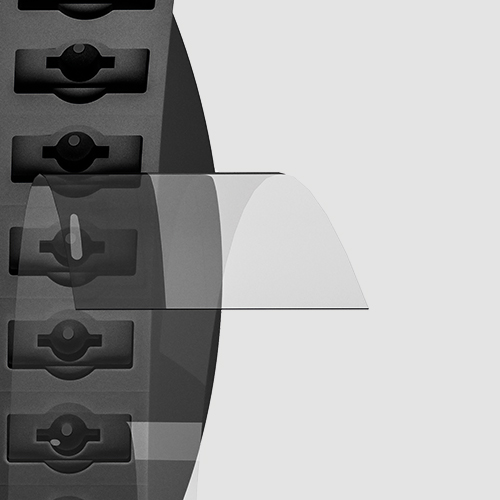

for carrier tape

ON-SITE SERVICE

Design – Production

Testing – Delivery

Design – Production

Testing – Delivery

We also offer on-site expertise on system and product development.

We would be happy to provide support for geometric design, handling and processing of your components.

Product Scan

With highspeed-cameras

Iso Certification

DIN ISO 9001

Just in time

Europe or worldwide

Rothe Injection Moulding Process

Shape your ideas

Shape your ideas

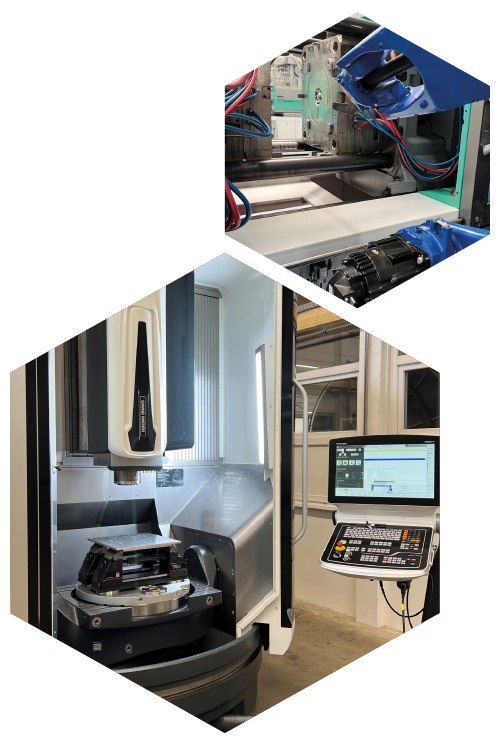

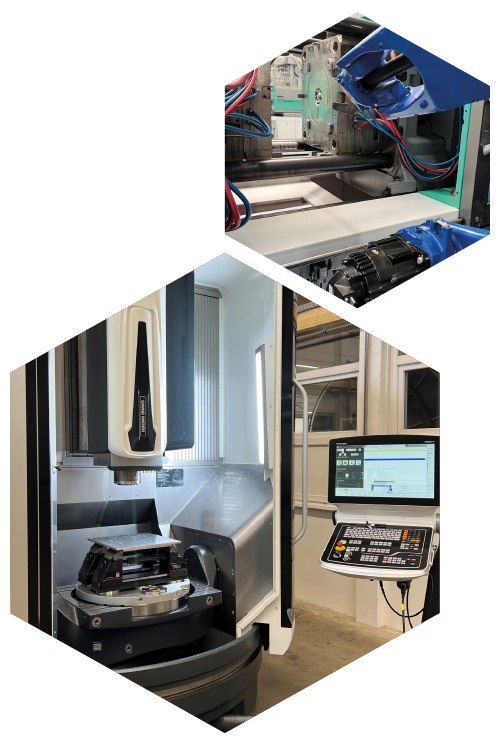

CUSTOMISED CREATIONS USING INJECTION MOULDING PROCESS!

In-House design department and mould

production with state-of-the-art machinery

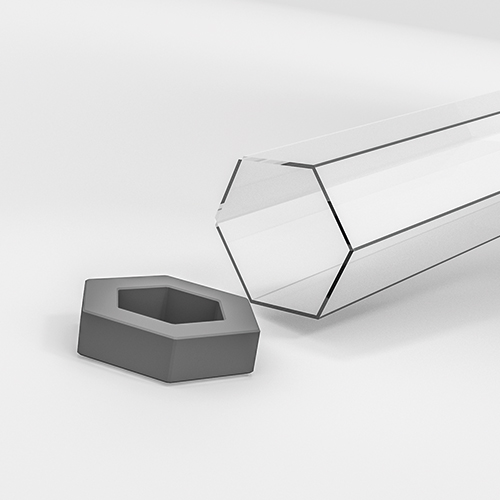

We make our injection moulded products from thermoplastic materials. Our high quality standards ensure that our products achieve the highest possible levels of accuracy and precision. Our machines can deliver maximum clamping forces of 50 t to 200 t, which means we can meet a wide variety of customer requirements – from complicated fittings to simple knobs.

We use injection moulding to produce products

when high precision counts. For example, the electronics, textiles and furniture industries, viticulture, office supplies and household article manufacturers appreciate our fast injection moulding production times.

Rothe Injection Moulding Process

Shape your ideas

CUSTOMISED CREATIONS USING INJECTION MOULDING PROCESS!

In-House design department and mould

production with state-of-the-art machinery

We make our injection moulded products from thermoplastic materials. Our high quality standards ensure that our products achieve the highest possible levels of accuracy and precision. Our machines can deliver maximum clamping forces of 50 t to 200 t, which means we can meet a wide variety of customer requirements – from complicated fittings to simple knobs.

We use injection moulding to produce products

when high precision counts. For example, the electronics, textiles and furniture industries, viticulture, office supplies and household article manufacturers appreciate our fast injection moulding production times.

Rothe as

Company

Company

ROTHE was one of the first manufacturers to produce thermoformed carrier tapes.

Today, we are one of the leading carrier tape manufacturers in Europe.